Description

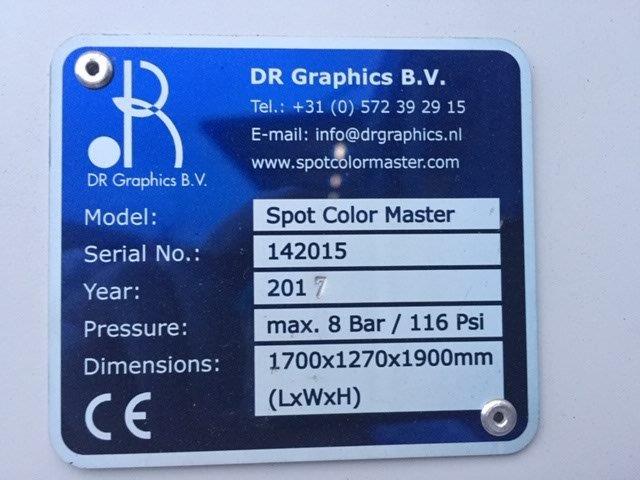

Colour dosing system for special colours with additional hobbock pump Technotrans TBA 25-18/9 DR GRAPHICS SPOT COLOR MASTER

Year of manufacture 2017

Serial no. 142015

Demovideo

https://www.youtube.com/watch?v=AhLTmJIpcFc

The Spot Color Master® is a newly developed colour mixing system.

It is especially suitable for packaging printing, for easy and reproducible mixing of colours (PMS/HKS) for spot printing.

It doesn’t matter whether you have been mixing your inks manually yourself up to now or whether you purchase ready-made mixtures,

you will benefit from a professional Spot Ink Master® mixing station.

You will significantly improve the efficiency, accuracy and consistency of your mixed inks.

You will save time and money and reduce your excess ink.

The Spot Color Master® has an ergonomic design and meets all safety requirements (two-hand operation).

All actions of the operator (control of the touch panel PC, colour mixing, exchange of containers) are carried out from a central position on the system.

on the system.

The platform of the scale (on which the empty mixing container is placed) is height-adjustable.

Touch Panel Pc with Easy Spot Color Software

is connected to the mixing scale on which the empty mixing container is placed.

With the help of the software, the employee can select the colour and the desired quantity.

He can either enter the colour name and colour code or select the colour on a scale.

Afterwards, the touch panel PC shows the next work steps for producing the mixture.

A progress bar informs the employee about the current status of the mixture.

At the touch panel, the employee can enter, remove or change colour formulations.

The basic version of the Spot Color Master® is suitable for 16 basic colours (conventional colour) in 2.5 kg vacuum containers as supplied by various manufacturers.

The 16 basic colours are divided into 8 colour ranges, each colour range consists of two basic colours.

Via the 2-stage dosing nozzles, the operator can produce exactly the desired amount of ink.

By pressing firmly on the switch, a large quantity of paint is dispensed in a short time,

by pressing lightly, he can add small amounts of paint in a fine stream.

After mixing a new colour, the containers of the basic colours do not have to be closed tightly again.

A cover that is moved back by pressure ensures that the colours do not come into contact with air or impurities.

Cleaning the metering nozzles after colour mixing takes only a few seconds and replacing the basic colour containers is also very easy.

Due to the very sophisticated construction and the use of durable basic materials (stainless steel and aluminium), the system requires only a minimum of maintenance.

The Spot Color Master® is cost-effective compared to other systems. The manual mixing system is easy to operate and is pneumatically controlled.

The Spot Color Master® works exclusively with compressed air.

It requires only 1.5 sqm of floor space.

Power supply is required for the scales (optionally with touch panel PC).

The platform of the scale is height adjustable.

Advantages

Cost saving – no paint build-up, efficient use of paint, little paint residue in containers

Time saving – quick and easy use

Accurate dosing – from 0.1 grams

Environmental friendliness – The Spot Color Master® helps to avoid environmental damage

Efficiency – Fast production of almost any spot colour at any time

Low maintenance – Quick and easy cleaning, low use of cleaning agents

Investment – low purchase price compared to other systems

Quick return on investment – low cost of equipment, low cost of spot colour production and low excess ink provide quick return on investment

Control – system works with compressed air

Technical data

Dimensions: 1700 x 1270 x 1900 mm (L x W x H)

Pressure: Max. 8 Bar (116 PSI)

Power supply: 100-240V AC – 50/60Hz – 1,5A Power supply for touch panel PC and scale: 12 V – 5,0 A

Container for basic colours: 2.5 kg vacuum container

Colours: RAL 7035/5007